AR8000 BULLETIN PAGE

Archive originally from the AOR-UK website in 2008, edited in 2022 by AOR Ltd. In Japan.

This information is supplied as a convenience to our loyal customers still using discontinued legacy AOR receivers.

Please note that the information is supplied “as is” without any support nor obligation. This model is no-longer accepted for repair and none of the parts are available anymore.

This information is supplied as a convenience to our loyal customers still using discontinued legacy AOR receivers.

Please note that the information is supplied “as is” without any support nor obligation. This model is no-longer accepted for repair and none of the parts are available anymore.

AR8000 Installing the DS8000 Speech Inversion Decoder

The DS8000 may be fitted to the AR8000 to provide analogue speech inversion descrambling, however not all types of speech inversion can be addressed by this option, primarily it is intended for Japanese cordless phones and some UK PMR446 transmissions etc.Click here to download the DS8000 fitting sheet.

TOP

AR8000 Discriminator Output

The discriminator output on the AR8000 is taken from pin 11 on U1. U1 is a TK10489 on the middle IF board.To get to the correct board first split the set by removing the screws in the battery compartment and at the top of the set. The set is then split in two main pieces. The board that the discriminator output is on the board in the rear half of the set. This is the IF board and needs to be removed.

To remove the IF board unscrew the nuts off each encoder on the top of the set. Next remove the two screws in the bottom of the board, and make sure the battery terminals that come through the board are straight. Gently ease the board away from the rear of the set.

U1 is located on the rear of the board that has just been removed. The discriminator output is taken from pin 11 of the TK10489 and a suitable earth.

TOP

AR8000 Opto Scout (Reaction Tune Modification)

The hardware modification includes adding a small jack to the radio to make it possible to connect the Scout™ with a flexible cable using 2.5mm phone jacks cables, and plugs. The modification described will permit easy connection from the Scout™ to the radio for reaction tune operation. This modification may however void the manufacturer's warranty. Keep this in mind and make sure you are aware of the possibility.Having been warned, it can be stated that the addition of the jack described here as easily done by a qualified electronics technician who is experience in working on two-way radios and scanners. Careful soldering of the wires to locations is necessary. If you are not experienced at soldering or taking apart hand-held radios you should seek assistance from a qualified technician.

Disassemble the radio and check the jack location against the picture. Make sure all the batteries are removed and that the power adapter is disconnected.

The jack being installed is a 2.5mm (3/32") phone jack. The center or tip connection from the Scout carries data to the radio. The wires used are number 24 stranded. In the AR8000, the wire lengths are short, a little more than an inch.

It is not necessary to drill a hole for the jack. locate the position of the hole relative to the power jack as shown in the picture. Tale a few minutes to see that the jack location will not interfere with the PC boards when the radio is re-assembled. To create a hole in the plastic case , use an X-Acto knife and place the point in the center of the desired location. Rotate the blade creating a hole in the soft plastic. Keep checking the hole size against the jack to make sure that you don't make it too large. It may be necessary to bevel the edge of the hole for the nut to fit on the jack. Some people feel that it is easier to create the hole in this manner than to use a drill (if a small drill is available, it becomes a simple operation but hold some protective material such as a wood block inside the cabinet of the AR8000 to prevent the drill from raking all the components from the inside of the radio!

The ground connections can be made where ever it is convenient. The picture shown positions that work well. The data connection in the AR8000 is taken directly from a chip resistor (as shown). Solder carefully to prevent damage to the resistor. Check for continuity between the nut on the outside of the jack and the ground connection to the radio's PC Board using a tester. If this checks out and polarity is not reversed then re-assemble the radio.

Power up: When the Scout is twitched on, a display self-test is performed. The self-test consists of illuminating all front panel display segments and annunciators for approximately two seconds, followed by displaying 'SCOUT' for another two seconds and then the communications LANGUAGE enabled for another two seconds. The Scout then begins operation in the operating mode selected by the FILTER and CAPTURE switches (AOR AR8000 or CI-V ICOM).

Changing the position of the CAPTURE switch during the display self-text will toggle the serial communications language between CI-V and AR8000. The default communication speed is 9600bps, experiment with CR/LF or place the AR8000 into NEW_USER_MODE, the parameters will then be correct! Place the AR8000 in 2VFO mode, remember, reaction-tune will only occur when active new frequencies are clocked by the Scout. When new transmissions are encountered, the AR8000 will react and follow the display of the Scout immediately, after a period of monitoring recall the SCOUT MEMORIES to select which frequencies you wish to store into the AR8000.

TOP

AR8000 Keypad Replacement

The AR8000 keypad comprises of a complete membrane with carbon printed contacts. Eventually with use, the carbon will deplete resulting in failure. There were two types of replacement keypad as spare parts, standard (original) and 'hard shell' (later)... the 'hard' type has a cover over the printed letters to prevent them from wearing off. Both are now discontinued and not available anymore.A few customers have commented on slight difficulty when fitting the later type of keypad on earlier sets and feel that the later keypad may be very slightly larger (the front case holes of the later sets providing greater clearance) so have had to carefully enlarge the clearance with glass-paper etc.

Before any work is carried out, place the set on a bench covered with a duster to prevent the set being scratched.

1) Remove 2 x screws (silver colored) in battery compartment.

2) Remove 2 x screws on side panels. These are the small black screws located next to the rubber side pieces. On each side, remove only the screw located nearest to the rear panel.

3) The front panel complete with the rubber side pieces can now be removed. To do this, slight force is needed pulling the two case halves away from each other. Do not lever the halves apart and do not twist them apart as inside connector pins may be bent.

4) With the front case half removed, the main circuit board now has to be removed from it in order to expose the keypad. To do this, remove 5 screws (silver colored) holding the board in place and unclip the speaker connector.

5) Carefully lift the board away from the case noting that the side switch panel will also lift away with the main board (there is no need to separate the two).

6) The keypad can now be lifted out of the case.

If any contamination has been deposited onto the board contacts, this can be cleaned away by light rubbing with a non-residue solvent and cloth. Refitting is the reverse of the above procedure. Care must be taken to ensure that the new keypad is situated the correct way up and with all its keys located in their slots in the case front before refitting the board. Care must also be taken to make sure that when mating the two halves together again, all of the connector pins locate correctly. It the two halves are pressed directly together keeping both sides parallel, then no problems should arise. Do not over tighten any of the screws. Power up the set and check the operation of all the keys.

TOP

AR8000 Wandering "Birdies"

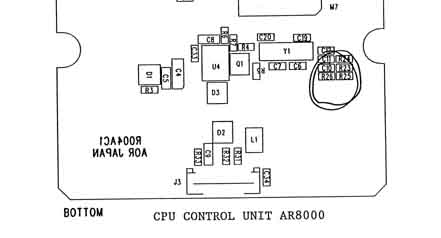

The floating birdies appear to be an interaction between the two DC-DC inverters of the I.F. PCB and ceramic crystal of the CPU PCB. When the set is fully assembled, both boards come close together and probably interact.The frequency of the CPU crystal is 4.91MHz, it is easy to locate the crystal on the CPU PCB. Simply remove the two screws in the battery compartment and the two (rear half) case screws on the side of the receiver near to the top. The receiver will part into two... the crystal is on the CPU half near the center of the board. It is soldered directly to the PCB and looks very similar to a miniature fuse.

This crystal may be replaced with a *metal cased* crystal package style HC49/4H being recommended (half height)... a watch style crystal may be even better. Of course the legs cannot pass through the PCB so lay the crystal on its side soldering the legs to the PCB crystal pads keeping them as short as possible.

Any frequency above about 4.2 MHz will be okay (the pitch of the beep will change though) but if you want to retain the REMOTE CONTROL / CLONE capability then you need to be very close to 4.91 MHz.

TOP

AR8000 Loose BNC Socket

Before any work is carried out, place the set on a bench covered with a duster to prevent it being scratched.1) Remove 2 x screws (silver colored) in battery compartment.

2) Remove 2 x screws on side panels. These are the small black screws located next to the rubber side pieces. On each side, remove only the screw located nearest to the rear panel.

3) The front panel complete with the rubber side pieces can now be removed. To do this, slight force is needed pulling the two case halves away from each other. Do not lever the halves apart and do not twist them apart as inside connector pins may be bent. This will leave the RF and IF boards connected together along with the top panel and rear case.

4) Remove the three rubber knobs on the top panel. These can be removed with a fairly strong pull and twist motion. If the knobs have gone soft or the rubber inside them has been damaged, it is best to replace them.

5) Remove the nuts holding the volume, squelch and encoder controls to the top panel. These are not usually very tight and can be loosened with a suitably pointed pair of pliers.

At this point it is also a good idea to withdraw from the battery compartment the two battery terminals which pass through the sockets on the IF board. Note that the ends of these contacts may be bent over and will need to be straightened before removal.

6) Undo the two screws holding the PCB in place and withdraw the board from the set by lifting the bottom of the board (to separate the connector between IF and RF boards) before withdrawing the controls from the top panel.

7) The rear of the BNC socket should now be visible. Note; some sets may have an earth strap which will have to be de-soldered.

If you are intending to just tighten the BNC socket, this can be done without any further dismantling, but, it is much easier if the entire RF board is removed from the rear case (three screws - two at rear and one in center) and then the top panel removed from the RF board (solder joints to BNC center and earth points).

8) The BNC can now be tightened using a pair of pointed pliers.

It can be quite difficult to get it very tight, but one trick is to hold the actual BNC socket by placing an old BNC plug onto it and holding that with a large pair of pliers, tightening the nut with the pointed pliers.

The problem here is that if you manage to get enough force between the two pliers, the lugs on the BNC can be sheared off.

Once tight, a spot of sealant can be used on the nut to keep the socket in position. A blob of super-glue could be used although this can make it impossible to remove the socket in the future should it ever require replacing. Note; do not use screw-lock, as this can make the plastic top panel brittle.

9) If the antenna wire link was broken, it can be replaced easily at this point.

The original one fitted is a solid wire link threaded through a very small bead (usually white in color, it is not an inductor!).

A simple piece of wire soldered in place will replace this or, better still, add a small piece of flexible wire to prevent any future breakage.

If you are careful, the small bead can be slid off the original wire and threaded onto the new link (it usually has a spot of glue holding it on) although this is trickier than it sounds (and is debatable if its omission makes any difference at all).

10) Rebuild the unit in reverse order to the above.

Don't forget to re-solder the BNC earth. Although this is slightly flexible, it is a good idea to solder it once the RF board and top panel are refitted to the rear cover to get it in its correct position.

Take care to put the control pots through the top panel before pushing the IF and RF board connectors together. Similarly make sure that the front section and IF boards are positioned correctly before pushing the sockets together.

It is a good idea to re-fit the battery terminals before the front panel is fitted. Bend over any protruding wire from the back of the battery sockets with a pair of pliers - this will prevent the battery terminals coming loose or dropping out.

Don't over tighten the control pot nuts and make sure that they are fairly central in their recesses. The rubber knobs should just push on again.

11) Test your work.

TOP

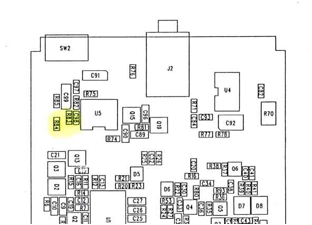

EARLY AR8000 - won't always switch on

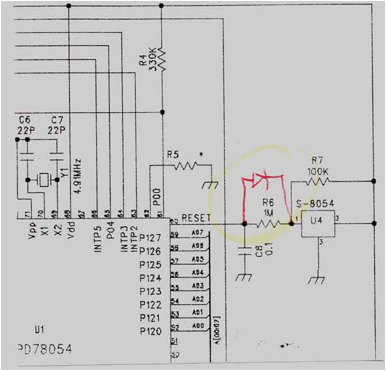

A 'few' reports have been received suggesting that the AR8000 will not always switch back on again once switched off, especially when using NiCads. Sometimes the LCD lamps illuminate and other times the set does nothing at all (occasionally just two lines of text are displayed at boot-up).This is a minor tolerance problem due to a high value resistor (1M OHM) in part of the reset circuit. The problem is not that it won't switch on, but rather one inverter doesn't switch off !

The remedy is SIMPLE and involves the fitting of one diode such as a 1SS268 etc. (Fitted to all production units from about serial 10500 upward).

| 1. Remove the battery cover & Nicads. |

| 2. Remove the two screws in the battery compartment. |

| 3. Remove the two side screws nearest the rear case... it is not necessary or advisable to remove all four screws. |

| 4. Carefully separate the two case halves. |

| 5. Locate the 1M OHM surface mount resistor on the microprocessor PCB (R6). Fit a diode across the 1M OHM resistor - it is easier to anchor between the regulator S-8054 (far right pin with set upright) and C8. An 1SS268 diode is used simply because it is small and fits easily but a standard 1N4048 or similar may be used to equal effect. If a 1SS268 is used (double diode SMD package) then only one diode is used so one leg is unused. |

| 6. Reassemble and test. |

|

|

TOP

AR8000 BANDSCOPE bandwidths

The bandwidth is center frequency (the frequency you are listening to) PLUS + MINUS five divisions:| USB/LSB/CW | approx. 3kHz per division regardless of step size, giving a maximum bandwidth of about 28 - 30kHz. |

| AM/NFM/WFM | approx. 10kHz per division when step size is 12.5kHz or less when step size is 25kHz or above, the bandwidth per division is equal to the current step size i.e. 30kHz, 50kHz, 100kHz, 200kHz etc. |

TOP

AR8000 'PLL ERR' display

If the 'PLL ERR' message is displayed when the batteries have only slightly discharged (the receiver works okay from external supply), add a 10pF capacitor to the I.F. PCB in parallel with R33, this should prevent the PLL unlock.TOP

AR8000 low battery indication

Occasionally it is possible for the LOW BATTERY message to appear on the LCD prematurely. The 'low battery' message should appear when the battery voltage typically drops to 4.2V and the 'battery error' message is displayed when the voltage typically drops to 3.5V (at which point the receiver stops functioning).The low battery display is monitored by the CPU via a potential divider (pair of series resistors) R25 (33k OHM) and R26 (100k OHM) on the CPU PCB. If incorrect results are displayed, adjust the values of R25 & R26.

TOP

AR8000 squelch splutter (audio mute)

The squelch operation on the AR8000 is controlled by the squelch line entering the microprocessor on pin 63. The audio mute is controlled by the microprocessor from pin 11. There is very little time delay between the action of these two lines. The squelch signal operates very quickly with respect to the RF input into the receiver. Signals with levels close to the threshold can therefore produce a broken recovered audio (audio mute).For early productions the squelch threshold was 0.2uV going to 50uV fully clockwise making the squelch setting quite critical. Later productions had a far narrower (better) range of 0.15uV to 1.5uV.

The mute delay time constant is controlled by R81 (100k OHM) and C96 (0.1uF) on the I.F. board. Increasing the time constant of this circuit gives a far 'nicer' audio mute response (i.e. removes any squelch chopping in and out) but doesn't affect the actual squelch performance with regard to signal, search and scan... there is a slight side effect of a very brief 'shhhh' noise at the end of transmissions prior to the squelch closing.

Just altering C96 to 2.2uF or 4.7uF (or even paralleling 1.0uF) gives a second or so delay which appears to be plenty to remove the squelch chattering on smaller signal levels. The actual squelch action with regard to RF performance is unaffected as only the audio mute had been modified.

TOP

AR8000 squelch 'blindness'

It is possible for the AR8000 squelch to remain open irrespective of the controls position (even fully clockwise) WITH NO SIGNAL PRESENT.1. Place the receiver in [2VFO] mode.

2. Enter a VHF frequency into VFO 'A' such as 145.400MHz NFM.

Ensure there is no transmission.

3. Switch to VFO 'B' by pressing [2VFO].

4. Enter a frequency into VFO 'B' such as 5.505MHz USB. Ensure that the receiver is picking up a signal (so that AGC is being produced).

5. Press [2VFO] to swap back to VFO 'A'. WHITE NOISE will be audible and cannot be muted even with the squelch control fully clockwise.

6. The squelch will then close if:

a. if a good strong signal appears then departs

b. Press the [MONI] key

c. Rotate the tuning [DIAL]

d. Re-enter the wanted frequency via the keypad

The above has been reproduced on ALL sets irrespective of serial number or production batch, it must be considered as a 'characteristic'.

TOP

AR8000 locked out memory - CPU reset

There is a known situation in which the AR8000 can be made to reset. This will happen if you press [A=B] to transfer a locked-out memory channel to VFO. The receiver will appear to function perfectly but will rest when next switched off / on again.If you wish to transfer a PASS CHANNEL to VFO, use the [ENT] key to transfer the frequency to the temporary VFO (rather than 2VFO) as described in the operating manual (or unlock the locked-out memory channel first).

TOP

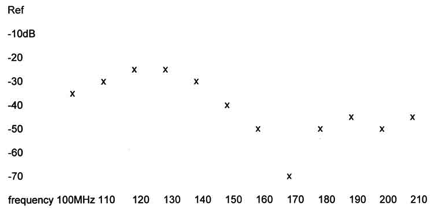

AR8000 supplied aerial frequency response

A crude test carried out on the AR8000 antenna (RA8000) shows quite a large dip around the area of the VHF marine band. Results were obtained by simply injecting a 0dBm signal into an (un-calibrated VHF) antenna approximately 2 meters away from the AR8000 antenna connected to the 50OHM input of a spectrum analyzer. Telescopic aerials provide far better results, especially for marine monitoring but are less concealable and more prone to mechanical damage.

TOP

AR8000 stuck on lower case memory banks

A few AR8000 operators have found that their sets have automatically reverted to LOWER CASE memory channels when manually selecting memory locations. This has been found to be the result of enabling select scan mode.With one or more memory locations tagged for select scan, the AR8000 will automatically select the CASE of memory location to be that of the first tagged location. Selection of the other CASE memories is possible but has to be selected every time a location is entered. Any subsequent tagged locations make no difference.

For example:

If memories a01 & A02 are tagged for select scan, then when manually selecting a memory location, the set will automatically go to the lower-case memories unless specifically requested otherwise.If memories a03 & A02 are tagged, the set will default to upper case locations in manual select.

If however, the first tagged memory location in upper- and lower-case memories is the same (i.e. a04 & A04), then the set will not automatically default to either case. Memory retrieval will behave as if select scan is not enabled.

TOP

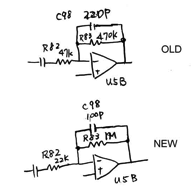

EARLY AR8000 audio scan component change

On early production units the audio scan / audio search facility may fail to stop on low-modulated signals such as 12.5kHz NFM transmissions.This is likely to be due to a lowering of AF gain in NFM to reduce the possibility of microphonic behavior. This action has incidentally lowered the level of signal path to the CPU which monitors whether the received signal is modulated or unmodulated.

To compensate for this change in level, the component values around U5(B) have been changed:

| Component | Old | New |

|---|---|---|

| R82 | 47k OHM | 22k OHM |

| R83 | 470k OHM | 1M OHM |

| C98 | 220pF | 100pF |

|

|

This component change was applied to all later production units.

One possible side effect, when a tape recorder adapter (CR8000) is connected when receiving a strong high-level AM signal, some distortion may be experienced.

TOP

AR8000 RS232 S-meter level

Using the LM command to the AR8000 through RS232 control, a theoretical signal level response can be obtained with up to 64 steps. In practice, the number of steps is little over 40.The response levels may vary slightly from set to set but for each set, the level is very consistent. Levels taken from one of the later production units are as follows:

TOP

AR8000 top panel knobs

As time passes, the top panel knobs may appear to loosen, this is more apparent on earlier units. To the user, the on/off switch appears not to function but in reality the knob is simply slipping round-and-round and no longer has enough friction to activate the on/off click switch.The knobs have a rubber type composition and appear to chemically react with the metallic material of the control shafts over a period of time. The later AR8000 knobs have a harder composition and thicker walls, in fact it is quite difficult to pull the later type knobs off the control shafts.

When replacing the top panel knobs, clean the shaft with a cloth or tissue to remove any residue before fitting the replacement knob. It is common to find a green fluid present on the control shafts.

Remember, the Vol/On/Off and Squelch knobs have 'dots' printed on them while the encoder knob is blank.

TOP

AR8000 Battery contact springs

The two battery contacts in the top right- and left-hand corners of the AR8000 provide the battery feed through the case to the main PCBs. They pass through small holes in the case and locate into sprung sockets fitted to the PCB. This provides a versatile method of connection and allows battery contacts to be replaced without the need for removing any case parts - but it has its drawbacks.The battery contacts may come out with the batteries when they are removed (especially if the batteries are a tight fit). This is no problem if the board socket remains in place when the contact is pushed back into place, but the sockets can also be pushed away from their location when re-inserting the contact.

Later sets overcame these problems by bending the end of the battery contacts over slightly after the wire end had passed through the socket. This was done before final assembly. These battery contacts cannot be removed without removing the case but also do not come out accidentally.

To replace or re-fit the battery contacts:

Remove the battery cover and batteries.Remove the two screws in the battery compartment.

Remove one screw from each side panel on either side of the radio (it’s probably best to choose the screws nearest the rear panel).

The two case halves should now pull apart. Note that a small amount of resistance will be experienced as the two inter-board sockets are being pulled apart.

The battery contacts and their sockets are now exposed on the middle PCB.

If the battery contacts are bent over, straighten them with a pair of pliers before pulling them out through the battery compartment.

If the battery contacts are already out, check that the sockets are straight and upright on the PCB to allow the contacts to be re-fitted.

If the set has had a hard life, check that the metal section of the socket is still springy and making a good connection with the battery contact. With the battery contact removed, the socket contact should return to the same position as the two unused sections of the socket next to it. I.e. the gap where the battery contact has pulled out from should close up.

If worn, it is possible to replace it with one of the unused sections of the socket.

Briefly how to do this:

Remove the three control knobs.

Remove the three lock nuts (fine pliers should do).

Unscrew the two board screws.

Remove the board.

Unsolder the offending socket.

If removing both sockets, simply re-fit each socket in the others position (hence an unused section now becomes a used section).

If only removing one socket, the spring contacts can be removed and exchanged - Click the solder end out of the socket and bend up slightly, press the lug hidden underneath and withdraw the contact. Exchange it with one of the unused ones and refit.

Re-assemble in reverse to the above (note that new control knobs may have to be fitted).

Re-fit the battery contacts through the holes in the battery compartment and into the sockets.

Using a pair of pliers, bend over the protruding end of the contact slightly to prevent it coming out again. This may not be possible if the contacts are very short. If this is the case, before pushing them fully home, put a small amount of super-glue on the section of the contact to be pushed into the case hole and/or side slots.

Re-assembly is the reverse of the above procedure.

Take care that the two inter-board contacts fit together correctly and that the side panels fit into their slots.

Now refit your batteries and test your work.

Additional note:

Three other battery contacts are fitted to the set. These are a ‘double’ contact items and are located by a slot at each end and three plastic lugs molded into the case. These do not generally cause any problems but on later sets have a spot of glue in the slots and on the lugs to add to their robustness. It is a good idea to carry this out at the same time with the aid of a tube of ‘super-glue’. Take care to keep the glue away from the spiral section which makes contact with the battery – ‘super-glue’ makes quite a reasonable insulator.TOP

AR8000 DC socket replacement

A 1.3mm concentric power socket is fitted to the AR8000. Although reasonably robust, it is only a small socket and may eventually fail after several years of hard use. Alternatively with rough use or a lot of movement when connected to an external power source, the solder connections may eventually break.Either of these problems are easily rectified by someone reasonably competent with a small soldering iron. At worse the socket will have to be replaced.

To carry out the work:

Remove the battery cover and batteries.Remove the two screws in the battery compartment.

Remove one screw from each side panel on either side of the radio (it’s probably best to choose the screws nearest the rear panel).

The two case halves should now pull apart. Note that a small amount of resistance will be experienced as the two inter-board sockets are being pulled apart.

The CPU / display board remains attached to the front and top panel, rear (RF/VCO) and center (IF) boards remain attached to the rear panel.

The power socket is now visible on the center PCB.

The battery contacts and their sockets are also now exposed. If the battery contacts are bent over, straighten them with a pair of pliers before pulling them out through the battery compartment.

If the battery contacts are already out, check that the sockets are straight and upright on the PCB to allow the contacts to be re-fitted.

Remove the three control knobs. These should just pull off, although they can be very stiff. If old, worn or gone soft, it is a good idea to use this as an opportunity to replace them. If replacing them, remove any traces of oil from the shafts. Some sets also had a green sealant on the shafts. Remove any traces of this. Note; leave re-fitting of the knobs until the very last job after testing the radio. Having to remove them again may damage them.

Remove the three lock nuts now revealed (a pair fine pointed pliers will do this if care is taken).

Remove the two board screws.

Lift the center PCB straight away from the rear panel and then withdraw the control pots from the top panel. Again, resistance will be experienced due to a connector in the center of the board.

With the underside of the board now exposed, the power socket can de-soldered and removed or simply re-soldered if the joints have fractured.

When refitting, for additional robustness, a small amount of solder can also be applied to the two exposed parts on the upper side of the socket.

If the PCB solder pads have fractured or lifted from the board. The only option is to bridge the broken section with a small length of suitable wire. Luckily all PCB tracks going to the socket connections are clearly visible, so this should present too many problems.

A spot of glue on the underside of the power socket might add to its robustness – this could also hold the socket in place while it is being soldered.

Re-assembly is the reverse of the above procedure. Take care when fitting the boards together to ensure that inter-board sockets are mated together correctly.

Refit the battery contacts before the cases are joined and bend the protruding end of the wire over to prevent the battery contact from being able to come out again accidentally.

When fully assembled but before fitting the control knobs, connect the power supply and test your work. Also check battery operation.

When you’re satisfied that everything is working normally, fit the control knobs.

TOP

Please note that the information is supplied “as is” without any support nor obligation. This model is no-longer accepted for repair and none of the parts are available anymore.

www.aorja.com